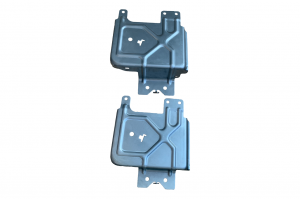

Extension Quarter Wheel/House Outer part

Part Name:

Extension Quarter Wheel/House Outer RR RH/LH

Material Grade: RC5754

Material Size: 1.5mm x 1292mm x 243mm

Stage Process: 800T Progressive Tool

Cavity: R and L parts out

Press Machine: 1200T Mechanical

Feeder Machine: used for COIL trial material

Inspection Tool: Checking fixture, Laser scan, CMM

Lead Time: 4 months

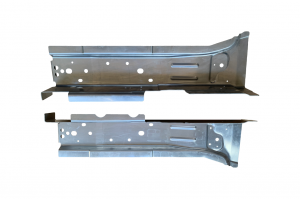

Technical Key Point:

Part quality with split and thinning issues and countermeasure

Background:

Stamping part with split issue is common in the process of product forming, only in the early time use analysis software to simulate and identify the cause of potential split failure, according to the causes of split and thinning then effectively control, in order to timely avoid product quality issues.

When this part in the preliminary layout process and forming simulation, it was found that there was a risk of split and thinning in the below areas. In order to avoid split and thinning in actual production, we apply to modify the trim edge here to the customer to improve this issue.

Conclusion:

Stamping split is the most likely quality defects in drawing and flanging processes, which will directly affect the strength of the parts and reduce the service life of the products. So when the split issue occurs in the parts, it will do scrap treatment, which virtually reduces the production efficiency and increases the production cost. Therefore, effective prevention in the early stage and quick response to solve defects are urgent and very necessary.

Our service advantage:

Fast & Flexible

After the customer sends the data, we will hand it over to the specially assigned person of the design department for docking, communicate the customer’s product requirements one by one, quickly make the process evaluation and quotation scheme, and send the scheme and quotation the next day.

Lower Cost & Higher Quality

a. We offer best products and services at a competitive price.

b. Select perfect and good stamping process.

c. Make rational use of materials.

d. High quality stamping die.